2022 WJTA Basics & Beyond Virtual Short Course

With the cancellation of WJTA's in-person 2021 Conference & Expo, WJTA's popular daylong, pre-conference WaterJet Technology Basics & Beyond Short Course will be presented virtually. The Basics & Beyond provides an applied introduction to waterjet technology and in-depth treatment of key applications.

The 2022 Basics & Beyond Virtual Short Course is delivered by an expert faculty from industry and academia. The course will be presented in a series of two-hour sessions with recordings and supplemental materials available to registrants.

The Virtual Short Course is chaired by Hugh B. Miller, Ph.D., Associate Professor, Colorado School of Mines.

Course Registrants: click here to access the online course modules and materials

The Virtual Short Course will be presented in four 2-hour digital sessions. The course is scheduled to take place in January 2022.

Click each topic to view more details.

Session One: Tuesday, January 11, 2022

10:00 A.M. - 12:00 P.M. CST

-

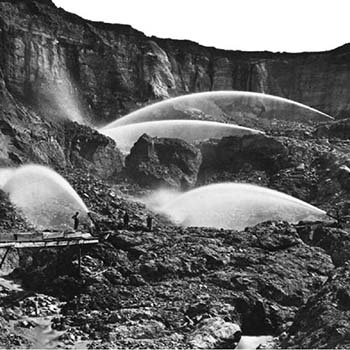

Waterjet Technology: Introduction & History • (David Summers, Ph.D.)

Waterjet Technology: Introduction & History

David Summers, Ph.D., Curators' Professor Emeritus of Mining, Missouri University of Science and Technology (MS&T)

- Water use in mining from Jason and the Argonauts, through the Romans, to use in California and Russia

- Cutting harder rock, higher pressure development and its use in industry, the advent of abrasive waterjets and the advent of abrasive slurry jets

- Robotic use and dangerous applications, combinations and the future potential including cavitation

After working in the British National Coal Board and getting degrees in mining at the University of Leeds, Dave Summers went to what is now the Missouri University of Science and Technology (Missouri S&T, formerly the University of Missouri-Rolla) to lead a team to develop waterjet cutting and use. As a result, he was there when abrasive jets, hydro-demolition, hydroexcavation, and other now common uses were being developed. With recognition for the group becoming international and leading to several awards, Dave is also proud to have been one of the founding members of the WJTA.

-

Applications of Waterjet Technology • (Darrell Terpenning)

Applications of Waterjet Technology

Darrell Terpenning, Vice President Sales, NLB Corporation

- How waterjets are used

- Rotary hand lances

- Automated systems

- Variety of applications

Darrell Terpenning joined NLB Corporation in 2013 as the vice president sales at NLB Corporation covering the United States and Canada. He received his bachelor's degree from Cedarville University in 1986. Darrell started his career as a contractor focused on cleaning automotive paint shops both domestically and internationally. In 1999, he joined an industrial services contractor based in the Midwest expanding his experience into new applications. From 2001 through 2012, Darrell led the sales and operations for a major filtration supplier to industrial plants.

-

Equipment Considerations • (Hugh B. Miller, Ph.D.)

Equipment Considerations

Hugh B. Miller, Ph.D., Associate Professor, Mining Engineering Department, Colorado School of Mines

- Fundamentals of equipment selection

- What matters and why

- System design configuration

- Nozzle design and selection

Hugh Miller is an Associate Professor in the Mining Engineering Department at the Colorado School of Mines (CSM), where he teaches courses and conducts research in a variety of specialized areas including waterjet technology and hydroexcavation, excavation engineering, and occupational safety. Prior to entering academia, Hugh worked 13 years for several mining and engineering companies in capacities ranging from operations to management, including five years as director of operations for International Engineering Technology, Inc., and its waterjet research subsidiaries. With more than 25 years of experience related to waterjet technology and hydro-excavation, he has served on the boards of several companies and professional organizations, including WJTA, and has overseen numerous projects related to equipment development and waterjet technologies associated with mining, civil-construction, and drilling systems. Hugh recently served as the President of the Society for Mining, Metallurgy & Exploration (SME), a global professional organization serving the mining and heavy underground construction industries.

Session Two: Tuesday, January 18, 2022

10:00 A.M. - 12:00 P.M. CST

-

Occupational Safety & Health • (Frank G. Romito)

Occupational Safety & Health

Frank G. Romito, WJTA Master Trainer

- Waterblast safety is integral to both productivity and quality on all waterblast projects

- Scientific basis to all waterblast rules/best practices

- Other safety standards become even more critical when waterblasting

- Automation has the potential to significantly reduce employee exposures, but only when the entire system is inspected and proven to be safe

Frank G. Romito currently serves as a Specialty Equipment Advisor specific to safe hydroblasting practices, equipment, and WJTA/specialty training. With a background in pump service, accessory configuration, fabrication, instruction, and field testing, he regularly aids in project outfitting, training carry-out and administration, and equipment purchasing and recommendations. As a WJTA Master Trainer, Mr. Romito and his colleagues have implemented a fully remote system compliant with the WJTA's requirements to process employees, subcontractors, and industry partners towards certification for safe hydroblasting practices. Frank coordinates and provides WJTA training for third-party organizations as needed.

-

Cleaning Applications • (Jeff Hensley)

Cleaning Applications

Jeff Hensley, Technical Solutions Manager, StoneAge, Inc.

- Planning and selecting the best waterjet for your application

- Understanding pressure and flow in material removal

- Understanding pressure loss, both before the water leaves the nozzle and after the water leaves the nozzle

- Benefits of automated equipment

Jeff Hensley came to StoneAge Waterblast tools in 1995 and has since worked in all aspects of the business, including manufacturing, assembly, quality control, repairs, sales, and customer support. In his current position as technical solutions manager, Jeff provides training across all product divisions and safety procedures for StoneAge. As “hands-free” automated equipment grows more sophisticated, Jeff has developed a leading role in training others to safely set up, operate and maintain these powerful tools.

Session Three: Tuesday, January 25, 2022

10:00 A.M. - 12:00 P.M. CST

-

Field Cutting Applications • (Bill McClister)

Field Cutting Applications

Bill McClister, Industry Consultant

- Components necessary for field cutting

- Advantages of waterjet cutting

- Commonly used abrasives

- Hazards, including fire or explosion

- Applications and case studies

Bill McClister is an industry consultant. He is the former vice president of support services at Veolia North America, and he was employed there for over 36 years. A large portion of Bill's career was spent developing advanced tooling and accessories to support Veolia's waterjet cleaning activity. Bill played a major role in introducing UHP waterjet cleaning and abrasive waterjet cutting technologies to industrial applications. In 1987, Bill directed the waterjetting activity involved in the rescue of Jessica McClure, the “Baby in the Well.” Bill serves on the WJTA board of directors and on the WJTA Safety Committees for High Pressure and Vacuum Equipment.

-

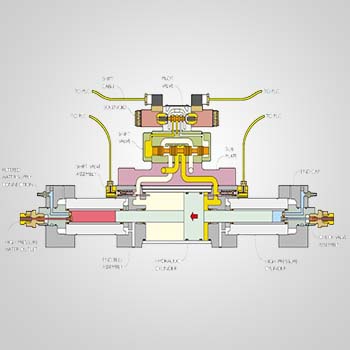

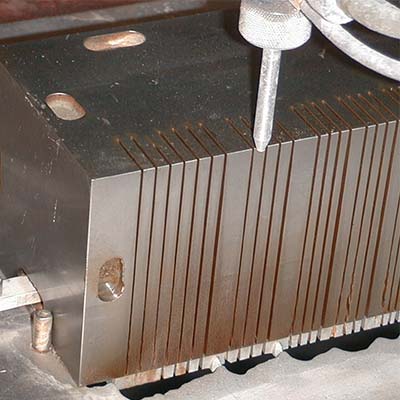

UHP & Abrasive Cutting Applications • (Mohamed Hashish, Ph.D.)

UHP & Abrasive Cutting Applications

Mohamed Hashish, Ph.D., Senior Technology Fellow, Flow International Corporation

- Introduction about UHP technology showing different pump systems and components. Also, the relationship between UHP parameters will be discussed.

- Jet formation techniques will be presented with a comparison among them. More focus will be on abrasive waterjets and its operational characteristics.

- Basic attributes of cutting features produced by waterjets will be presented and how these attributes are affected by the process parameters.

- Examples of waterjet systems for different applications will be presented.

- Machining Applications such as cutting, drilling, milling, turning and surface preparation will be discussed along with upcoming challenges.

Dr. Hashish is a senior Technology Fellow at Flow International Corporation. He graduated from Alexandria University, Egypt, in 1970 and obtained his Ph.D. in Mechanical Engineering from Concordia University in 1977. In 1980, Dr. Hashish invented the abrasive waterjet process, for cutting any material and continues to work on this technology today. Dr. Hashish also serves as an affiliate professor at the University of Washington. He has published over 350 papers and 120 U.S. and world patents in the areas of UHP and waterjet. He received the technology, service, and pioneer awards from the WJTA.

Session Four: Tuesday, February 1, 2022

10:00 A.M. - 12:00 P.M. CST

-

Coating and Corrosion Removal & Surface Prep • (Lydia Frenzel, Ph.D.)

Coating and Corrosion Removal & Surface Prep

Lydia Frenzel, Ph.D., Industry Consultant

- Coatings removal compared to industrial cleaning

- Comparison between abrasive blast and waterjet surface preparation

- How effective is waterjet cleaning in preventing corrosion?

- AMPP and ISO standards for coatings removal

- What is “flash rust, rust back, and rust bloom”

- Guidance on cleaning rates

Affectionately known as “The Water Witch of the West,” Dr. Lydia Frenzel is a recognized authority on surface preparation and has co-chaired the SSPC/NACE Committees on Coatings Removal by Water Blasting since 1985 and currently is a Working Group Convenor and U.S. subject matter expert to ISO TC 35 Coatings and Varnishes where she continues to advocate for pressurized water to removal coatings and corrosion. She bridges the corrosion industries represented by NACE, SSPC where she received the John D. Keene Award, and now AMPP, and the WJTA where she was a board member for 12 years and received the WJTA Pioneer Award. For her latest adventure through life, Lydia and husband Charles write novels under the pseudonym L.C. Frenzel

-

Sewer Cleaning • (Dana M. Hicks)

Sewer Cleaning

Dana M. Hicks, National Sales Manager, ENZ USA Inc.

- Applications: flushing vs. cleaning

- UHP cleaning

- Sanitary sewers and storm sewers

Dana Hicks has been a sales manager with ENZ USA Inc. for over 20 years, and he has been in the sewer and pipe cleaning industry for 27 years. Daily, he travels across the U.S. and Canada performing demonstrations and holding educational sessions for cities and contractors that do maintenance on all pipe sizes that are in a good to very bad condition. Dana received his bachelor's degree from Purdue University. He is a member of the WaterJet Technology Association (WJTA), the American Public Works Association (APWA), APWA Chicago Metro Chapter, Water Environment Federation (WEFTEC), and the National Association of Sewer Service Companies (NASSCO).

-

Hydrodemolition • (Troy Aldea)

Hydrodemolition

Troy Aldea, Capital Sales, NLB Corporation

- Hydrodemolition — What is it and what makes it work

- Advantages and considerations

- Applications

- Equipment and set-up

- Robotic vs. manual hydrodemolition

Troy Aldea has worked with NLB for over 33 years. He has held several positions on the NLB team over the years. He has been working with hydrodemolition equipment for over 25 years and has spent hundreds of hours on hydrodemolition work sites. Troy has involved with the design and upgrade of hydrodemolition equipment, and he works with individuals to set up hydrodemolition equipment configurations that best meet their specific business model.

Interested in becoming a sponsor? Contact Peter Wright at wrightp@wjta.org or call 314-241-1445 for details on sponsorship or media partnership opportunities.