Webinars

WJTA webinars are free to attend, and all registrants can access recordings for one month after the live webinar. Archived webinar recordings are available to WJTA members in good standing. Click here to learn about the benefits of membership.

Recorded Webinars

Turnarounds (part 1 of 4) – Increase Tool Time and Decrease Downtime Through Proper Job Planning

Bill Holladay, Xtreme Liquid Technologies

Recorded August 13, 2020

Turnarounds (part 2 of 4) – Risk Mitigation and COVID-19 Precautions

Bradley Coble, Covestro

Recorded September 3, 2020

Turnarounds (part 3 of 4) – Minimize Downtime Through Job Tracking and Proper KPIs

Bill Holladay, Xtreme Liquid Technologies

Recorded September 24, 2020

Turnarounds (part 4 of 4) – Dos and Don’ts of Exchanger Cleaning During Turnarounds

Bill Holladay, Xtreme Liquid Technologies

Recorded October 1, 2020

Confined Space Entry

Dan Lattner, First Strike Safety Solutions

Recorded October 13, 2020

Leadership in the Field: How to Successfully Manage Hydroblasting Operators

Jimmy Peck, MPW Industrial Services

Recorded November 5, 2020

Grounding and Bonding in Vacuum Operations

Richard Puig, Newson Gale, Inc.

Recorded December 10, 2020

Three Considerations That Can Make or Break the Effectiveness of Your Waterblasting Job: Quality Jetting, Managing Pressure Loss, and Controlled Rotation

Bill Shires, StoneAge, Inc.

Recorded January 21, 2021

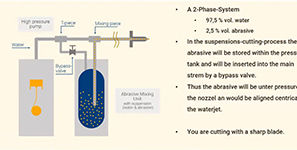

Wet Abrasive Blast Cleaning Technical Committee Update

Lydia Frenzel, Ph.D., Advisory Council, and Chris Fulmer, and Larry Fulmer, CESCO/AquaMiser

Recorded February 25, 2021

Modifying Existing Waterjet Units for Maximum Performance

Xavier Contreras, Gardner Denver Water Jetting

Recorded March 18, 2021

22,000 psi – Enough Power to Cut 12-inch Steel?

Ulf Behrens, ConSus-ANT/ANT AG

Recorded April 15, 2021

Proper Planning and Execution of Hydro-excavation

David Gonzalez and Bill Shaw, Evergreen North America

Recorded May 20, 2021