February 2014

High Pressure Hydroblasting Hose Failure and Life Cycle Analysis

Rick Pitman

EHST Vice President

PSC Industrial Services

www.pscnow.com

High Pressure Hydroblast supply hose serves a vital function in any Hydroblasting job regardless of the application. Whether automated or manual tools are used, all personnel levels, from job designers to workers, depend on the hose to consistently and safely deliver water from the pump to the tooling application. Hoses are expected to do this while performing under harsh environments and harsh treatment by workers. In spite of their critical role there is little or no published scientific data on life expectancy, in-field failure causes or methods to protect hose integrity.

History

Hydroblast supply hoses have traditionally been treated as a consumable item. Standard practice has been to run them until failure or near failure (in which case the reinforced steel braids are visible and broken) and then replace with a new hose. Systems for tracking the hose history from manufacture to disposal, as well as life cycles for performance, were non-existent. Anecdotal evidence revealed that everyone seems to know someone who has experienced a hose failure yet because most failures did not result in significant injuries they were not treated as a serious near loss. When significant injuries did occur they were not shared with the industrial community. This changed in September 2011 when PSC decided to share the results from a fatality associated with a hose failure as well as the lack of scientific industry knowledge regarding hose performance.

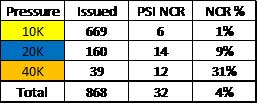

PSC commissioned a first of its kind study of High Pressure Hydroblast supply hose performance in November 2011. Supply Hose is usually purchased as an independent item and - with larger companies – usually from multiple suppliers. Taking a population of 868 hoses, which were fabricated between November and December of 2011, PSC tracked the performance of each hose in order to obtain quantifiable data regarding hose performance. For control PSC chose a single distributor – GHX – for all hose purchasing and managing. Certain safety and quality control upgrades were put into place beforehand that would make the PSC hose population unique for the Hydroblast industry including but not limited to:

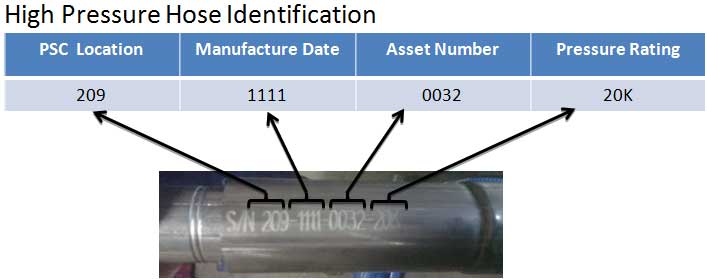

- Independent serial numbers for accurate hose tracking

- Installing abrasive covers for all hose types from 10K to 40K psi

- Removing hoses from the field once braids become visible

- Requiring an independent review of each hose annually to insure objectivity.

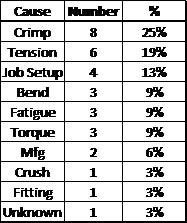

A process was designed so that all pressure related failures during the first year received a Non-Conformance Review (NCR) allowing each failure to be recorded and tracked. (Other NCR’s such as visible braids and separated abrasive covers are not covered in these results as they were removed from service before pressure failure). As might be expected the majority of pressure related failures resulted from issues which could be corrected by the end user. For example, investigations revealed that tension failures were caused from employees pulling on the hose ends during hose and tool movement which caused too much stress to be placed on the ends. A Shared Learning to the organization helped educate the workforce on the need to insure that hoses are held at a point that helps distribute and support weight more evenly during movement. A smaller but still significant number of NCRs resulted during the hose assembly process. For each NCR PSC’s Mechanical Integrity (MI) owner was able to isolate the cause, work practice or assembly method to correct the hazard. If it was a potential manufacturer or distributor issue the MI lead could quarantine other hoses from the same batch while investigation results were pending. By forming a working partnership with the hose distributor during the investigation process, both PSC and GHX were able to identify trends and implement company-wide improvements that simply would not be possible without a complete tracking and investigating system. As a result of this program PSC has realized a 50% reduction every six months on all pressure and visible inspection hose NCR’s since January 2012.

How long should a high pressure Hydroblast supply hose last?

The traditional answer within the industry supply chain is one million cycles of pressuring on and then pressuring off. No known scientific data exists to support this measurement. Historically hose manufacturers and distributors advise that a hose will fail from the outside long before the inside due to the constant friction from vibration between the hose and the ground making such a measurement unnecessary. Accordingly there has not been a universally recognized standard regarding when a hose should be pulled from service. While tires, for example, can be measured by miles or tread depth no such method exists for measuring the number of pressure cycles for Hydroblast hose. To be cautious PSC initially implemented a three year life cycle for supply hoses based on potential maximum usage from date of hose receipt to a maximum target life of 500,000 cycles. In 2013 the Hose Safety Institute (of which PSC is a member) of the Association of Hose and Assembly Distributors working in conjunction with the WJTA Hydroblast Safety Committee agreed on a recommended life limit of four years after hose receipt which would correspond to a maximum target life of 667,000 cycles for a safety factor of 33% from the traditional million cycle guideline.Independent Test Results – Year One

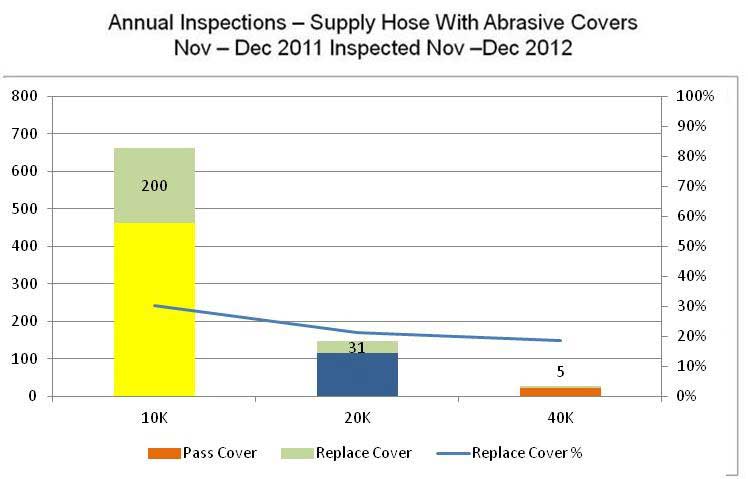

After 12 months of service the entire original test group was sent to an independent site for analysis. Results showed that abrasive covers were worn through and needed replacing in 27% of the hoses. However, in each case the actual outer rubber or plastic covering of the hose was protected and, upon passing a visual inspection and pressure test, was fitted with a new cover, then pressure tested and certified to be returned to service. Without the abrasive cover in place, the outer cover of the hose would have become worn to the point of exposing braids and significantly shortening the expected life of the hose. It is possible that with the addition of protective covers for all hose pressures the industry may reach the point where hoses have the opportunity to reach maximum hose life before being worn down by external friction. With abrasive covers costing a fraction of a replacement hose there is a quick return on investment for installing covers.

Visual Inspection Guidelines – Any of the following would result in a failed test and the hose being removed from service.

- Leaks at the hose fittings or in the hose.

- Damaged, separated or pulled back covers

- Cracked, damaged, deformed or badly corroded fittings.

- Other signs of significant deterioration such as blisters.

- Visible wires.

- Dents, twists, or kinks

- Discoloration of color coded hose cover

- Thread and seat connections

Excluding cover replacements, 4% of the test hoses failed visual inspection and were removed from service at one year.

Pressure Test Guidelines -

New hoses and hoses for re-certification should be pressure tested:

- Between 1.2 and 1.5 times maximum allowable working pressure

- Minimum of 30 seconds up to a maximum of three minutes

Of those hoses that passed visual inspection, 7% failed pressure testing and were removed from service.

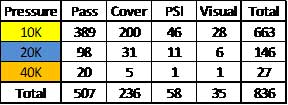

Full results are captured below.

12 Month Independent Test Results

Key Terms:

Pass: Passed visual and pressure test. Returned to service.

Cover: Abrasive cover replaced. Then passed visual and pressure test. Returned to service.

PSI: Failed pressure test. Discarded.

Visual: Failed visual test. Discarded.

Conclusion

It feels as if scientific data on High Pressure Hydroblast hose has grown relatively little since Frank Ofeldt created his first ‘High Pressure Jenny’ in 1927. However, pressures are much higher and the risk is much greater today. There is still much to be learned regarding hose performance, hose life expectancy, in-field failure causes and methods to protect hose integrity. By studying every hose, and learning how and why it failed, the industry not only learns to prevent hose failures, the industry also helps protect the workers who have the potential to be harmed when a hose fails.

This article is excerpted from the February 2014 Jet News, a benefit of membership in WJTA-IMCA. For more information on membership, click here.